(The Burn is pleased to share this article from our partner publication, Ashburn Magazine.)

THE MASK MAKERS

By Chris Wadsworth

Helpless.

That was one of the main feelings many people in Ashburn and elsewhere experienced as the coronavirus crisis grew. Helpless to protect themselves, their families and their neighbors, not to mention the local businesses they cared about that were suddenly struggling mightily.

And most of all — helpless to do something for the doctors, nurses and others in critical roles who were caring for the sick and at-risk without the proper gear — face masks and shields, disposable gloves and hair caps — known collectively as personal protective equipment, or PPE.

But just as in every time of crisis, people rose to the challenge. Most of us started social distancing. Friends checked in on friends. Neighbors shopped for neighbors. And people started buying gift cards and ordering carry-out meals from their favorite restaurants.

And then came the masks and the other PPE. People across Ashburn pulled out their sewing machines, fired up 3D printers or came up with other clever ways to help our brave medical professionals. If you have been on social media the past two months, it was a sight to behold.

Here are just a few of these caring individuals.

==========

DINA QURESHI

Late last year, Dina Qureshi had the sudden urge to learn how to sew. She’d never done it before, but she ordered a sewing machine online with the goal of making a new dress.

And then the sewing machine sat untouched in her closet as life got busy and the months flew by. What she needed was the proper motivation, and it came in the form of a pandemic.

“I heard on the news that health-care providers didn’t have enough PPEs, and I thought here was a great opportunity for me to finally learn to sew,” said Qureshi, who lives in Ashburn’s Westmoore community. “I got out my sewing machine and a friend showed me the basics. From the [Centers for Disease Control] website, I got the requirements for making masks. So I bought some fabric and started making them.”

Qureshi, who immigrated to America from Morocco in 2014, made more than 100 face masks in her first two weeks of sewing and gave a bunch to a friend who’s a nurse at the Inova HealthPlex in Ashburn. When word came that Inova wasn’t accepting homemade masks any more, Qureshi sought out other medical facilities that would. She sent 50 masks to Mary Washington Hospital in Fredericksburg.

When she’s not sewing, Qureshi is an engineer with Dominion Energy. She works on the overhead and underground relocation of power wires and equipment. But despite those impressive technical skills, there was a learning curve to making simple fabric masks.

“They have improved a lot from how they looked at the beginning,” she said with a laugh, adding she will keep sewing masks as long as there’s a need. “I’m happy that I’m doing something for the community. Something that might be small for me might help someone on the front lines from being exposed to the virus.”

At press time, her next batch of masks was headed to a hospital in Winchester.

==========

NATHANIEL GRANT

When the health crisis ramped up in March, business started to drop off at GAM Graphics & Marketing. The company’s president — Ashburn Farm resident Nathaniel Grant — was trying to figure out what he was going to do with all his employees who suddenly had a lot less work.

Then he heard about the desperate need for plastic face shields to protect healthcare workers. A lightbulb went off. The company could easily take the equipment it uses to make graphics and promotional displays and repurpose it for face shields.

“We had to source the plastic – that was the biggest problem – so much of the plastic had already been grabbed,” Grant said. “We sourced it and ended up getting a thousand sheets, and we can get six masks out of each sheet. We got the foam and rivets, and all my employees are just sitting there putting them together.”

Some of the shields produced at Grant’s Sterling facility have gone to StoneSprings Hospital near South Riding, as well as Reston Hospital and the Virginia Pediatric Group — all free of charge. The company also got several barrels of hand sanitizer, so Grant’s team has been bottling that for customers as well.

Grant admits the busy work has served several purposes.

“It’s mainly for the community because they couldn’t find them and it’s easy for us to do that,” he said. “And it definitely gives my people something to do. They were going stir-crazy sitting at home.”

==========

PEGGY TYREE

You know the quote about it being easier to ask for forgiveness rather than permission? Yeah, that applies perfectly to Peggy Tyree.

Tyree works at Belmont Station Elementary School in Ashburn as an instructional facilitator of technology, or IFT, meaning she coaches fellow teachers as well as students in the use of technology. When Loudoun County schools closed suddenly in early March, Tyree grabbed the school’s two 3D printers and took them home.

“I thought I would print out some of the work that the students had been working on as a way to keep them engaged,” she said.

But fate had different plans. A parent from the school heard about the printers and suggested she use them to print the parts needed for plastic face shields. It turns out there was a whole community of 3D printing enthusiasts — including IFTs at other local schools — who were sharing face shield plans and communicating with local facilities that needed them.

Tyree said the orders started coming in.

“I’m using the school’s plastic that I brought home with me, and I’m ordering lamination film from Staples, as well as having rubber bands and Ziplocks delivered,” Tyree said. “The printers have been running for 10 days straight.”

Shields created by Tyree and fellow instructors Patricia Smith from Discovery Elementary and Colette Bradley at Rosa Lee Carter Elementary have gone to the coronavirus floor at George Washington Hospital, the Inova Loudoun Rehabilitation Center in Leesburg and several assisted- living facilities. Among those is Falcons Landing in Sterling, which had multiple coronavirus cases among its health-care residents and staff.

Tyree started a fundraiser to replace Belmont Station’s plastic filament that she used in the 3D printers, and she hopes the good deeds she and the other IFTs are doing with the printers will earn their schools’ blessings.

“I never asked permission,” she said with a laugh.

==========

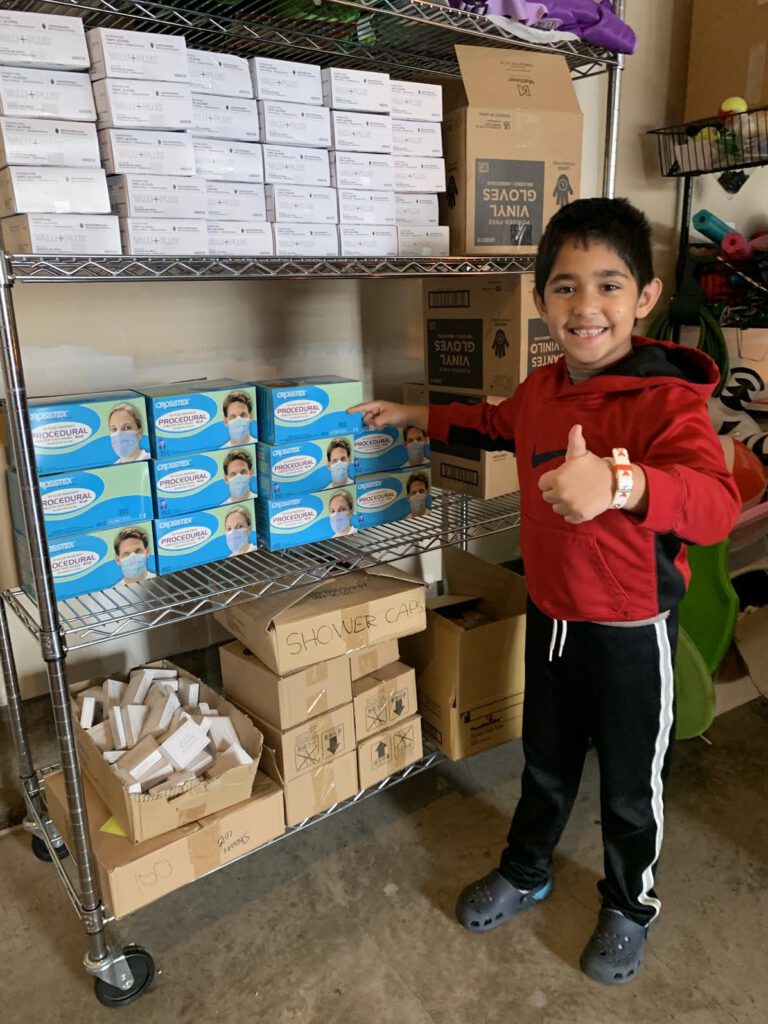

ZOHAIB BEGG

Zohaib Begg doesn’t know how to sew or have his own factory or a 3D printer, but the 7-year-old boy knew he just had to do something for the doctors and nurses at Inova Fairfax Hospital in Falls Church. After all, he knew them personally.

“Three years ago, they saved my life,” said Zohaib who lives in One Loudoun. “Now, I wanted to help the doctors.”